Newly designed 3D printed flexible and stretchy mesh could be used to create wearable supports such as ankle or knee braces and even implantable devices such as hernia meshes that support softer body tissues.

‘Scientists developed 3D-print stretchy mesh with customized patterns designed to be flexible yet strong, for use in ankle and knee braces. This could pave the way for new personalized wearable and implantable devices.’

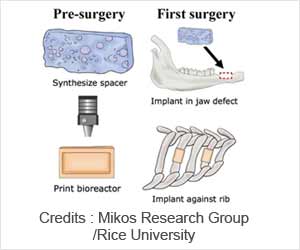

Now MIT engineers have designed pliable, 3-D-printed mesh materials whose flexibility and toughness they can tune to emulate and support softer tissues such as muscles and tendons. They can tailor the intricate structures in each mesh, and they envision the tough yet stretchy fabric-like material being used as personalized, wearable supports, including ankle or knee braces, and even implantable devices, such as hernia meshes, that better match to a person's body.As a demonstration, the team printed a flexible mesh for use in an ankle brace. They tailored the mesh's structure to prevent the ankle from turning inward -- a common cause of injury -- while allowing the joint to move freely in other directions. The researchers also fabricated a knee brace design that could conform to the knee even as it bends. And, they produced a glove with a 3-D-printed mesh sewn into its top surface, which conforms to a wearer's knuckles, providing resistance against involuntary clenching that can occur following a stroke.

"This work is new in that it focuses on the mechanical properties and geometries required to support soft tissues," says Sebastian Pattinson, who conducted the research as a postdoc at MIT.

Pattinson, now on the faculty at Cambridge University, is the lead author of a study published in the journal Advanced Functional Materials. His MIT co-authors include Meghan Huber, Sanha Kim, Jongwoo Lee, Sarah Grunsfeld, Ricardo Roberts, Gregory Dreifus, Christoph Meier, and Lei Liu, as well as Sun Jae Professor in Mechanical Engineering Neville Hogan and associate professor of mechanical engineering A. John Hart.

Riding Collagen's Wave

Advertisement

"3-D-printed clothing and devices tend to be very bulky," Pattinson says. "We were trying to think of how we can make 3-D-printed constructs more flexible and comfortable, like textiles and fabrics."

Advertisement

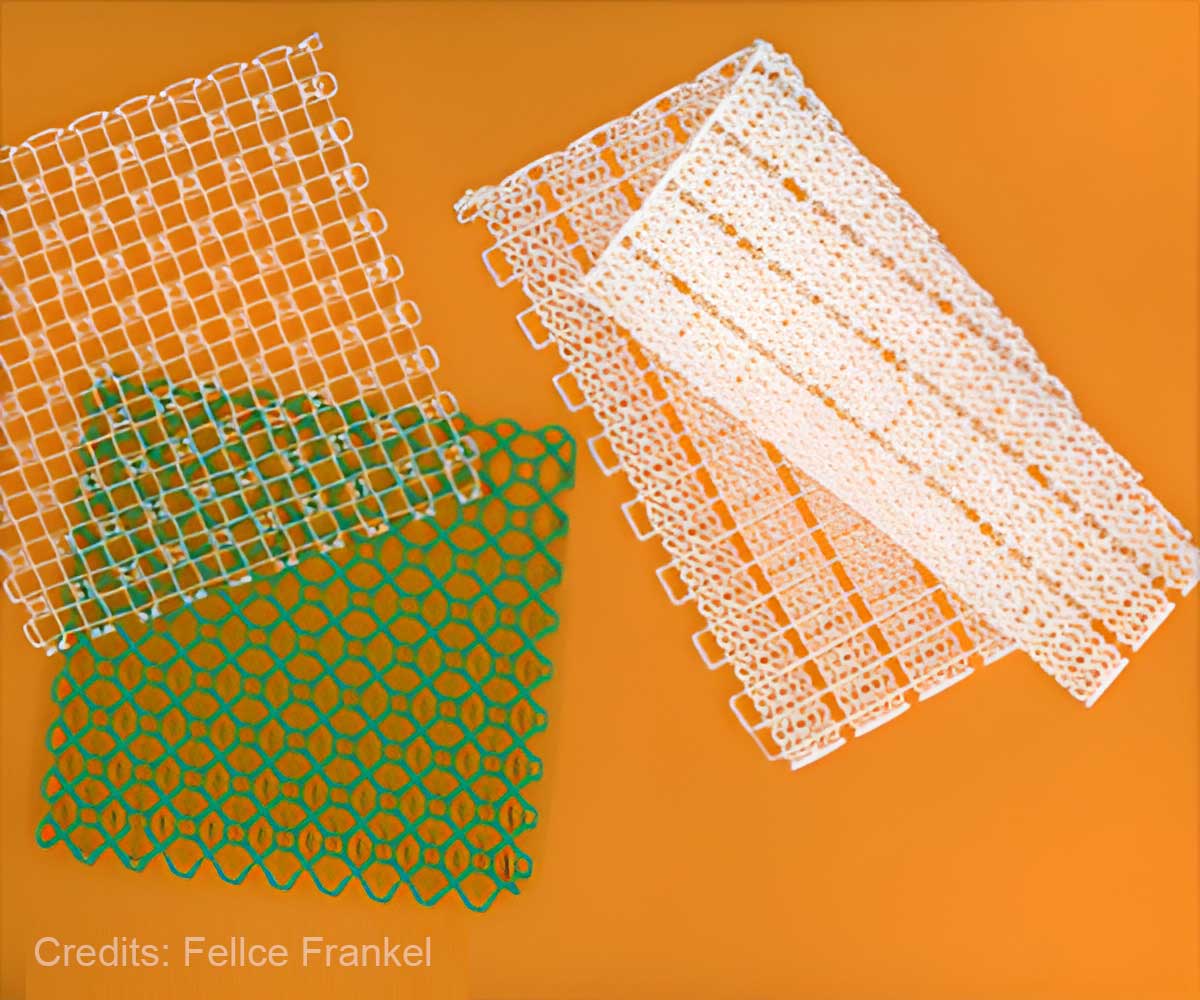

Inspired by collagen's molecular structure, Pattinson designed wavy patterns, which he 3-D-printed using thermoplastic polyurethane as the printing material. He then fabricated a mesh configuration to resemble stretchy yet tough, pliable fabric. The taller he designed the waves, the more the mesh could be stretched at low strain before becoming more stiff -- a design principle that can help to tailor a mesh's degree of flexibility and helped it to mimic soft tissue.

The research team printed a long strip of the mesh and tested its support on the ankles of several healthy volunteers. For each volunteer, the team adhered a strip along the length of the outside of the ankle, in an orientation that they predicted would support the ankle if it turned inward. They then put each volunteer's ankle into an ankle stiffness measurement robot -- named, logically, Anklebot -- that was developed in Hogan's lab. The Anklebot moved their ankle in 12 different directions, and then measured the force the ankle exerted with each movement, with the mesh and without it, to understand how the mesh affected the ankle's stiffness in different directions.

In general, they found the mesh increased the ankle's stiffness during inversion, while leaving it relatively unaffected as it moved in other directions.

"The beauty of this technique lies in its simplicity and versatility. Mesh can be made on a basic desktop 3-D printer, and the mechanics can be tailored to precisely match those of soft tissue," Hart says.

Stiffer, Cooler Drapes

The team's ankle brace was made using relatively stretchy material. But for other applications, such as implantable hernia meshes, it might be useful to include a stiffer material, that is at the same time just as conformable. To this end, the team developed a way to incorporate stronger and stiffer fibers and threads into a pliable mesh, by printing stainless steel fibers over regions of an elastic mesh where stiffer properties would be needed, then printing a third elastic layer over the steel to sandwich the stiffer thread into the mesh.

The combination of stiff and elastic materials can give a mesh the ability to stretch easily up to a point, after which it starts to stiffen, providing stronger support to prevent, for instance, a muscle from overstraining.

The team also developed two other techniques to give the printed mesh an almost fabric-like quality, enabling it to conform easily to the body, even while in motion.

"One of the reasons textiles are so flexible is that the fibers are able to move relative to each other easily," Pattinson says. "We also wanted to mimic that capability in the 3-D-printed parts."

In traditional 3-D printing, a material is printed through a heated nozzle, layer by layer. When the heated polymer is extruded, it bonds with the layer underneath it. Pattinson found that, once he printed a first layer, if he raised the print nozzle slightly, the material coming out of the nozzle would take a bit longer to land on the layer below, giving the material time to cool. As a result, it would be less sticky. By printing a mesh pattern in this way, Pattinson was able to create a layers that, rather than being fully bonded, were free to move relative to each other, and he demonstrated this in a multilayer mesh that draped over and conformed to the shape of a golf ball.

Finally, the team designed meshes that incorporated auxetic structures -- patterns that become wider when you pull on them. For instance, they were able to print meshes, the middle of which consisted of structures that, when stretched, became wider rather than contracting as a normal mesh would. This property is useful for supporting highly curved surfaces of the body. To that end, the researchers fashioned an auxetic mesh into a potential knee brace design and found that it conformed to the joint.

"There's potential to make all sorts of devices that interface with the human body," Pattinson says. Surgical meshes, orthoses, even cardiovascular devices like stents -- you can imagine all potentially benefiting from the kinds of structures we show."

Source-Eurekalert