Millirobots are objects coated with magnetic spray (M-spray) which is biocompatible and has biomedical applications like in catheter navigation and drug delivery.

TOP INSIGHT

Millirobots are objects coated with magnetic spray (M-spray) which is biocompatible due to which the objects can crawl, roll or walk. These have biomedical applications like in catheter navigation and drug delivery.

Read More..

The findings have been published in scientific journal Science Robotics, titled ‘An agglutinate magnetic spray transforms inanimate objects into millirobots for biomedical applications'.

How objects are transformed into millirobots?

Millirobots or insect-scale robots have been developed by scientists that can adapt to different environments for biomedical applications and exploration.

The glue-like magnetic spray is called M-spray which is composed of polyvinyl alcohol (PVA), gluten and iron particles. Dr Shen said,“Our idea is that by putting on this ‘magnetic coat’, we can turn any objects into a robot and control their locomotion. The M-spray we developed can stick on the targeted object and ‘activate’ the object when driven by a magnetic field.”

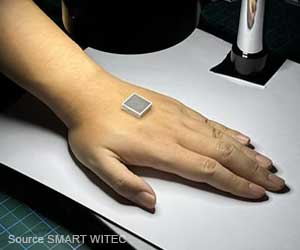

Magnetization of the coated object was done by subjecting it to single or double magnetization directions thereby controlling how the objects would move in a magnetic field. The coating was solidified by applying heat to the object. In this way, when a magnetic field is applied, the objects are converted into millirobots with different movements like crawling, rolling, flipping, walking on different surfaces like skin, glass, wood and sand.

Changing movements

These millirobots are special as they can be easily reprogrammed according to the different needs, on demand. The first co-author of the paper Dr Yang Xiong has stated that usually the robots have a fixed initial structure once it is constructed which restricts its versatility in movements.

But in the case of M-spray objects, the solidified M-spray coating can be wetted thereby making it adhesive like glue. Hence if a strong magnetic field is applied the alignment direction and the distribution of these M-spray particles can be easily changed.

Experiments were conducted where a faster 3D caterpillar movement in a spacious environment was switched to a slower 2D concertina (which is a musical instrument) movement for passing through a narrow gap, which proved that the same millirobot can be switched to a different movement.

Navigation and Disintegration Property

The feature of reprogramming movements was found useful in case of navigation to different targets. For testing the biomedical applications, the researchers conducted an experiment using a catheter (inserted into the body to carry out surgical procedure) which is widely used and demonstrated that M-spray catheter could perform sharp or smooth turns and the impact on motion stability and ability due to blood flow was limited.

Fast-steering and passing smoothly through an irregular and narrow space was possible by reprogramming the M-spray coated object. This reduces the risk of unexpected plunging in the throat wall which may occur during insertion.

Dr Shen said,“Task-based reprogramming offers promising potential for catheter manipulation in the complex oesophagus, vessel and urethra where navigation is always required.”

One more important feature of this technique is that with manipulation of the magnetic field, the M-spray coating can be broken into small powders on demand. Dr Shen has stated that the side effect of this break down that is disintegration is negligible.

He said,“All the raw materials of M-spray, namely PVA, gluten and iron particles, are biocompatible. The disintegrated coating could be absorbed or excreted by the human body.”

Testing Drug Delivery

An in vivo test (performed in a living organism) was performed in a rabbit using a capsule coated with M-spray to test the effectiveness and feasibility of this technique. The rabbits were first anesthetized and then by using radiology imaging technique the position of the capsule in the stomach was tracked.

When target was reached, the coating of the capsule was broken into powder by using an oscillating magnetic field. Dr Shen said,“The controllable disintegration property of M-spray enables the drug to be released in a targeted location rather than scattering in the organ.”

In a strong acidic environment that is in stomach (pH 1), the M-spray layer will start to disintegrate within 8 mins. If an additional PVA layer is present, the disintegration time is increased to 15 mins. If required, the coating can also be made to remain stable after 30mins in a strongly acidic environment by replacing the iron particles with the nickel particles.

Dr Shen said,“Our experiment results indicated that different millirobots could be constructed with the M-spray adapting to various environment, surface conditions and obstacles. We hope this construction strategy can contribute to the development and application of millirobots in different fields, such as active transportation, moveable sensor and devices, particularly for the tasks in limited space.”

Source-Medindia

MEDINDIA

MEDINDIA

Email

Email