- 3D Printing Technology in Pharmaceutical Drug Delivery: Prospects and Challenges - (https://www.omicsonline.org/open-access/3d-printing-technology-in-pharmaceutical-drug-delivery-prospects-andchallenges-2167-7956-1000e141.php?aid=64501)

- First FDA-approved, 3D printed Spritam drug for epilepsy now available - (https://www.3ders.org/articles/20160322-3d-printed-fda-approved-epilepsy-drug-spritam-now-available.html)

- 3D-Printed Drugs: What Does the Future Hold? - (http://www.asme.org/engineering-topics/articles/manufacturing-design/3dprinted-drugs-does-future-hold)

- A new chapter in pharmaceutical manufacturing: 3D-printed drug products. - (https://www.ncbi.nlm.nih.gov/pubmed/27001902)

- Novel Technology to Design and Manufacture Pharmaceutical Drug Products - (https://www.usp.org/sites/default/files/usp/document/our-work/research-innovation/research-innovation-3d-printing-drug-products.PDF)

- 3D printing in a pharmaceutical setting - (https://www.ispe.org/sites/default/files/membership/affiliates-chapters/nordic/events/2016/2016-nordic-3d-printing-of-pharmaceuticals-presentation.pdf)

- Three-dimensional bio-printing: A new frontier in oncology research - (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5309712/)

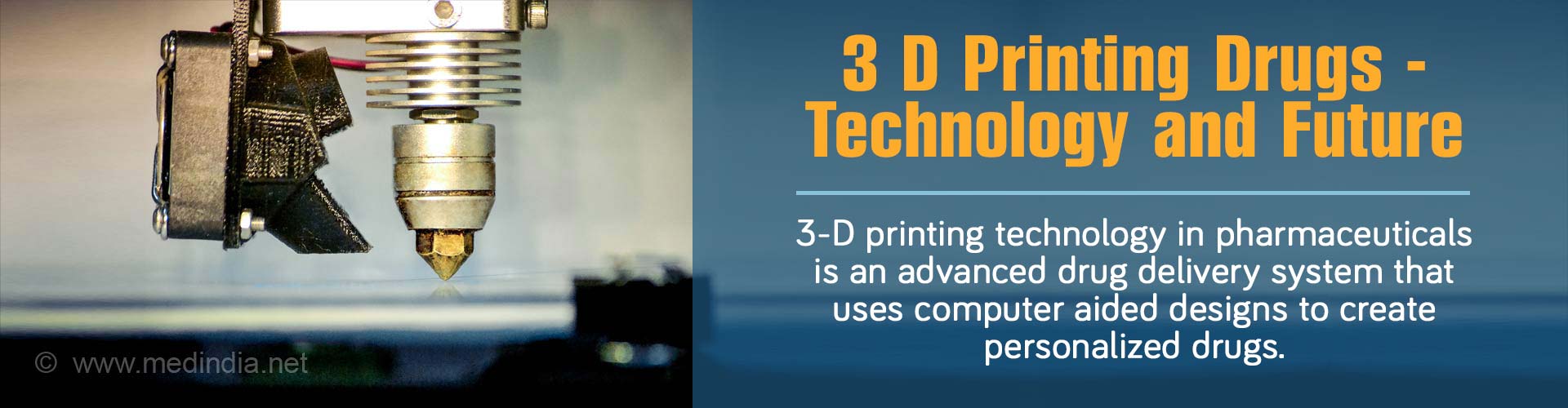

What is 3D Printing of Drugs?

Three-dimensional (3D) printing of drugs uses computer-aided designs to manufacture individualized pharmaceutical drug products.

The 3D printing (3DP) technology is already being used in the pharmaceutical field to manufacture 3D printed customized prosthetics, surgical implants, medical devices and 3D bio-printed tissue.

3D printing technology for medications is an innovative and cost-saving technology to deliver medications with ease.

This technology benefits both the doctors as well as the patients and treats common as well as serious medical conditions, from chronic pain to epilepsy. These are developed as patient-specific formulations, thus making the medication customized and more effective, with lesser side effects and economical than standard drugs.

There are reports of scientists developing 3D printed shapes which have been a challenge to manufacture conventionally e.g., 3D printed pyramid shaped tablets will become popular as they release medicament more rapidly than the conventional cylinder-shaped pills.

This technology is also known as pharmacogenetics, to make drugs specific to patients based on their DNA information.

U.S. FDA has approved one 3D-printed formulation of Levetiracetam (SPRITAM®), in August 2015. It is a drug used to treat certain types of epilepsy and manufactured by a company called Aprecia.

What is the Technology Used in 3D Printing?

A computer algorithm is developed to design and calculate dosages specific to patients, based on their clinical and biological parameters. The algorithm generates 3D printable files which are then used for making 3D printed drugs.

The process involves producing a 3D object by building the medication on a substrate, using computer-aided design models. The material is ejected from a printer on a horizontal plane to create a foundation of the object. The printer then moves along the z-axis, and a liquid binder is sprayed onto the object to a specific thickness. This process continues based on computer defined instructions. This technology is also known as Additive manufacturing (AM), Rapid Prototyping (RP) or Solid free-form technology (SFF).

Various techniques can be used to produce 3D printed pharmaceuticals or medications, e.g., Inkjet based fabrication, Direct-write, ZipDose®, Thermal Inkjet printing, Stereolithography (SLA), and Fused deposit modeling (FDM).

Inkjet printing: This technique involves spraying droplets of combinations of active ingredient and excipient (ink) into a substrate. The sprayed ink then solidifies on a powder substrate.

ZipDose®: This technology involves manufacturing a highly porous material which provides a personalized dose, with a high drug-load, low disintegration time and faster dissolution.

Thermal inkjet printing: This methodology facilitates dispensing extemporaneous solution of the drug on 3D drug scaffolds or films. It consists of a micro-resistor that heats a thin film of ink fluid, forming a bubble which expands to push the ink dropout out of a nozzle.

Material Jetting: In this case, a powder substrate is not required. The printers can print free-form structures that solidify drop by drop.

The company Aprecia uses its proprietary technology known as ZipDose® technology to manufacture Spritam tablets, which are 3d printed tablets. It uses a combination of formulation science and 3D printing to produce easy-to-swallow and rapidly disintegrating formulations of drugs. With the help of this technology, the tablets disintegrate in the mouth with a tiny sip of liquid.

The process involves depositing a powdered blend to form the first layer. Next, the binding fluid is precisely deposited onto the first layer. This helps to bind the powder blend and prepares it to adhere to the next layer. This process is repeated several times, and the final product turns out highly solid yet highly porous.

What is the Purpose of 3D Printing of Pharmaceuticals?

As an advanced technology, the medications need to be designed or tailored to individual patient’s need, taking into account biological, genetic and environmental factors.

There could be situations, where specific treatment regimens need to be administered to patients with chronic illnesses.

3D printing can also be used to develop medications with controlled release of drugs, and those containing fixed-dose combinations.

3D printing will help in developing approaches for providing “best fit” solutions to individual patients, who are not able to benefit from other known technologies.

3D bio-printed human models, tissues or organs are being used in oncology therapy to develop newer anti-cancer drugs. Use of these models would help formulate anti-cancer drugs quickly and accurately as compared to the two-dimensional cell cultures and animal models.

What is 3D Printing of Illegal Drugs?

3D printing technology can be misused to produce counterfeit or illegal drugs.

The 3D printers or printing software can be tampered with and be used to manufacture or mask illegal drugs on a large scale.

The cyber hackers can gain access to any innovator’s software, and the same can be misused to produce illegal 3D medications.

The drug regulation authorities will need to establish strict guidelines to ensure that the manufacturing and marketing of 3D printed drugs are safe and reliable.

What is the Future of 3D Printing of Drugs?

3D printing of drugs is a break-through innovative technology, which will create more opportunities to develop safer and efficient technologies for prescription drugs.

In future, 3D printing facilities can be set up at hospitals, clinics, pharmacies and in patients’ homes, to facilitate treatment by creating patient-specific regimens.

What are the Advantages and Complications of 3D Printing Technology for Pharmaceuticals?

This technology provides many advantages:

- The bonding of powdered materials between liquid materials to generate 3D printed medications makes the formulations very porous, such that they dissolve as soon as they come into contact with a small quantity of liquid. This facilitates administering medications to children, physically impaired patients or those suffering from seizures

- Computational algorithms are generated taking into account the biological factors of individual patients, e.g., weight, age, race, kidney, and liver functions, which helps in optimizing the specific patient’s drug dose.

- Small batches can be manufactured, based on the individual preference of size, color and, flavor.

- Hospitals could manufacture small batches on-demand, eliminating the need to maintain an extensive inventory of generic formulations.

- There is no need to provide extended shelf life for a product.

However, this technology is still in a nascent stage and has its challenges. These include a selection of excipients, optimization of print fluid parameters/specifications, the functioning of nozzle, optimization of the process, and software validations.

What are the Regulatory Challenges?

Since this is a new technology, there are many regulatory challenges associated with the same. At present, there are no guidelines for manufacturing or quality control of 3D printed drugs.

The FDA regulates the quality of a standard drug product; however, 3D printed drugs are not yet regulated by FDA.

The regulatory approval process and classification of these 3D printed drugs is not yet defined.