Working with robotics company Boston Dynamics, based in Waltham, Mass., the researchers began developing the material as part of the Chemical Robots program of the Defense Advanced Research Projects Agency (DARPA). The agency was interested in "squishy" robots capable of squeezing through tight spaces and then expanding again to move around a given area, Hosoi says - much as octopuses do.

Hosoi said that the robot must be able to exert a reasonable amount of force on its surroundings if it is going to perform meaningful tasks.

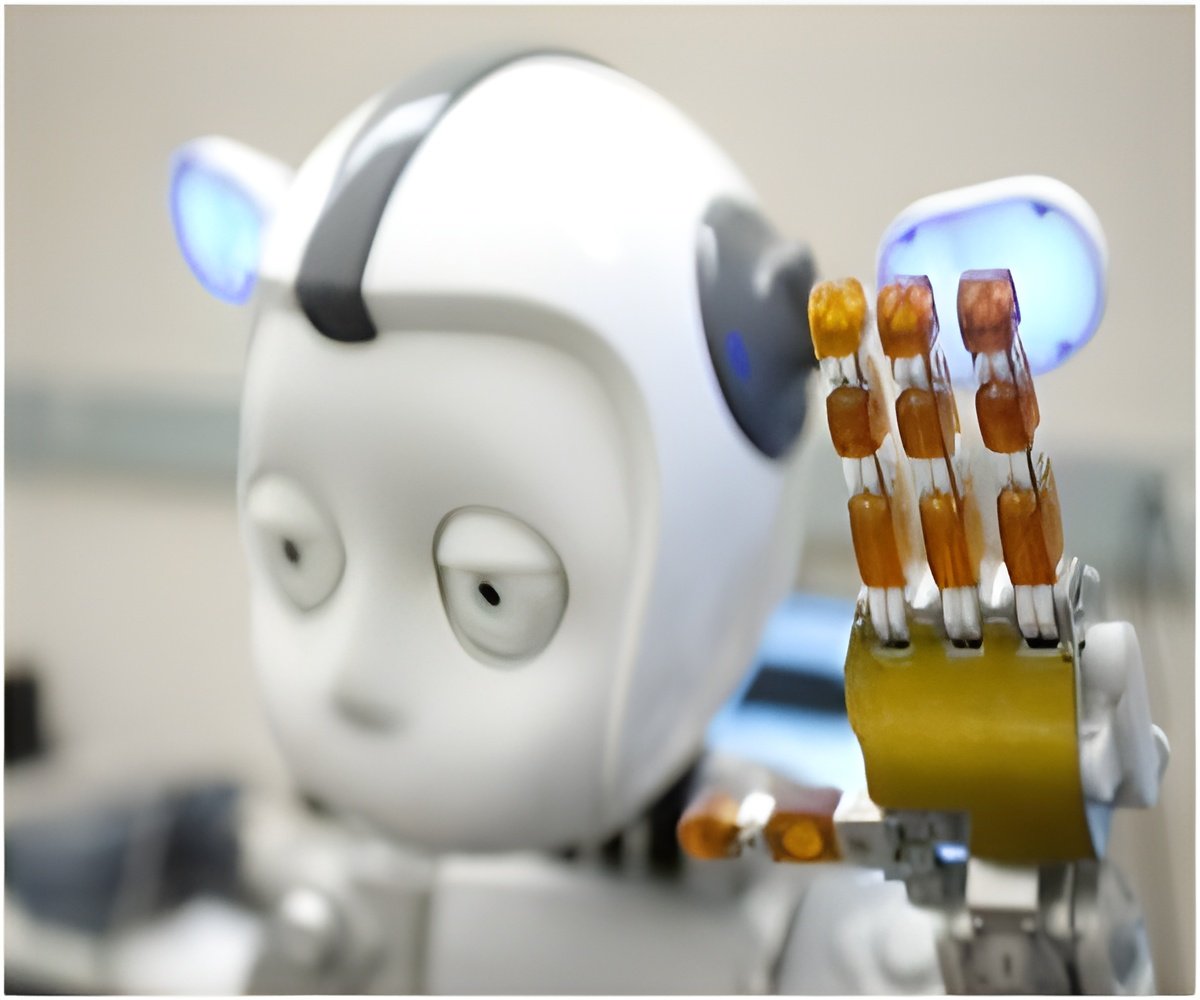

To build a material capable of shifting between squishy and rigid states, the researchers coated a foam structure in wax. They chose foam because it can be squeezed into a small fraction of its normal size, but once released will bounce back to its original shape.

The wax coating, meanwhile, can change from a hard outer shell to a soft, pliable surface with moderate heating. This could be done by running a wire along each of the coated foam struts and then applying a current to heat up and melt the surrounding wax. Turning off the current again would allow the material to cool down and return to its rigid state.

Chengs said that to build the material, the researchers simply placed a low-cost polyurethane foam in a bath of melted wax and then squeezed the foam to encourage it to soak up the wax.

Advertisement

Source-ANI