Highlights

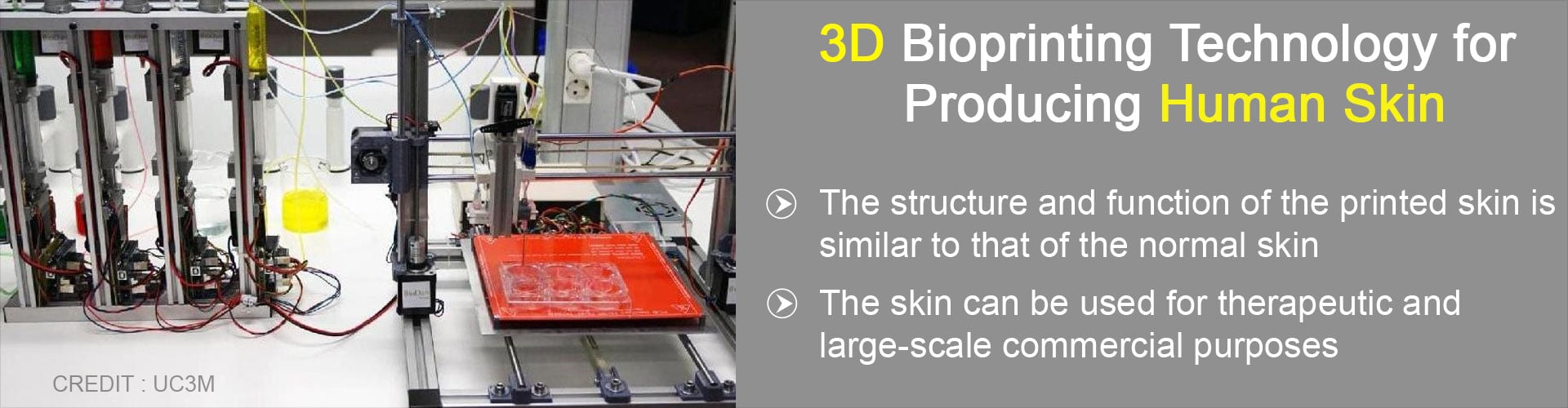

- Human skin can now be produced using 3D bioprinting technology.

- Bioinks are used for 3D printing of the skin.

- The skin can be used for therapeutic applications like transplantation or for large scale industrial processes.

It replicates the natural structure of the skin with:

- a first external layer-the epidermis with its stratum corneum, which acts as protection against the external environment

- thicker and deeper layer-the dermis that consists of fibroblasts that produce collagen, the protein that gives elasticity and mechanical strength to the skin

According to Juan Francisco del Cañizo, of the Hospital General Universitario Gregorio Marañón and Universidad Complutense de Madrid researcher, "Knowing how to mix the biological components, in what conditions to work with them so that the cells don't deteriorate, and how to correctly deposit the product is critical to the system."

The act of depositing these bioinks is controlled by a computer, which deposits them on a print bed in an orderly manner to then produce the skin.

Two types of tissues can be created:

- allogeneic skin, from a stock of cells, done on a large scale, for industrial processes

- autologous skin, which is made from the patient's own cells, for therapeutic use, such as in the treatment of severe burns

"This method of bioprinting allows skin to be generated in a standardized, automated way, and the process is less expensive than manual production," says Alfredo Brisac, CEO of BioDan Group.

These tissues can also be used to test pharmaceutical products, as well as cosmetics and consumer chemical products where current regulations do not require animal testing.

Researchers are looking for ways to print other human tissues.

This research from Carlos III University of Madrid has recently been published in the electronic version of the scientific journal Biofabrication.

Reference

- José Luis Jorcano et al. 3D bioprinting of functional human skin: production and in vivo analysis. Biofabrication ; (year) doi.org/10.1088/1758-5090/9/1/015006

Source-Medindia