Highlights:

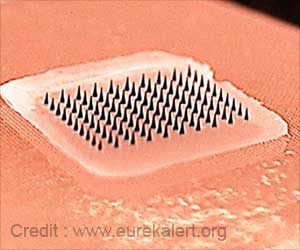

- Microparticles are being developed through 3-D fabrication to deliver multiple doses of vaccines or a drug through a single injection

- The microparticles vary in structure so that they release their contents at different times

- Further research, if successful, could result in better coverage of vaccines, especially in the developing world

This approach could be particularly useful in the underdeveloped or developing nations with reduced manpower to administer multiple vaccines and poor patient compliance. With further development, it may be possible to develop microparticles that could cover all the vaccines that should be administered in the first two years of life – thus, once the child is born, he/she could be administered a single injection, and the child would not need another vaccine for the next one to two years and yet be protected.

The scientists carried out several tests to evaluate their model:

- The scientists tested the property of pulsed release from the microparticles by filling microparticles with varying structural properties with fluorescent- labeled dextran. They found that the structurally-different particles released the dextran at different times, in vitro, as well as, when administered to mice. Leakage of the contents before time was not observed.

- The heating of the microparticles to seal them did not affect the enclosed trivalent inactivated polio vaccine (IPV), which is among the most thermolabile vaccines in use.

- The scientists injected mice with structurally-variant microparticles containing ovalbumin, a substance that is used experimentally to achieve an immune response. The particles released the ovalbumin at two different times. The final immune response obtained with the single dose was similar to that produced by two separate injections with double the doses.

Further research would be needed to ensure that the medication or the vaccine remains stable within the particles over longer durations.

The new technology of developing such microparticles could also have several other applications in medicine. It may be possible to bring about the release of the medication or vaccine on the application of a stimulus. For example, in the presence of certain bacteria in the body, the microparticles can be designed to release an antibiotic to fight against the infection.

Reference:

- McHugh KJ, Nguyen TD, Linehan AR, Yang D, Behrens AM, Rose S, Tochka ZL, Tzeng SY, Norman JJ, Anselmo AC, Xu X, Tomasic S, Taylor MA, Lu J, Guarecuco R, Langer, Jaklenec A. Fabrication of fillable microparticles and other complex 3D microstructures. Science 2017:Vol. 357, Issue 6356, pp. 1138-1142. DOI: 10.1126/science.aaf7447

Source-Medindia