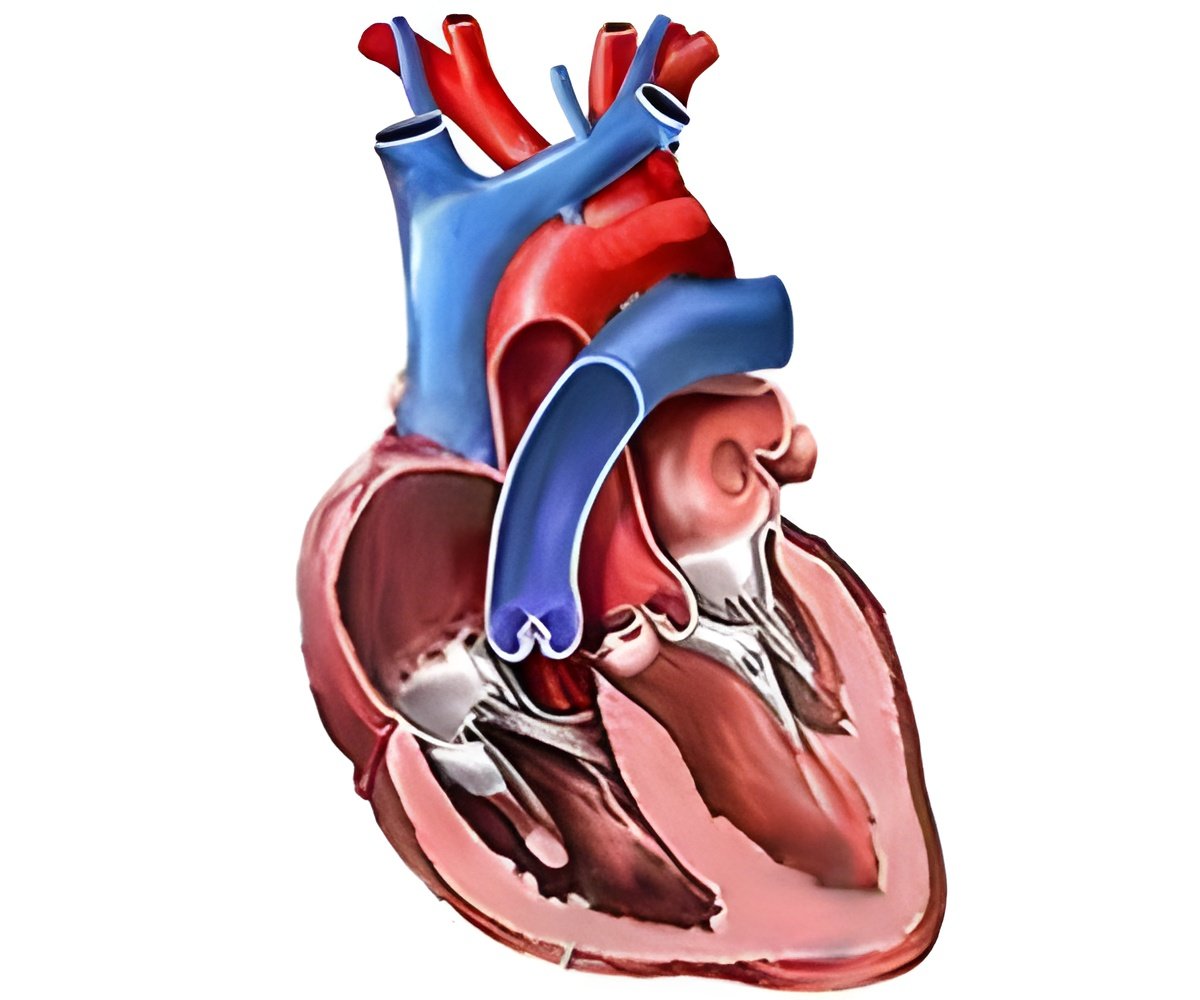

For example, in the future, doctors may repair the damage caused by heart attack by replacing it with tissue that rolled off of a printer.

The biofabrication technology, called dynamic optical projection stereolithography (DOPsL), was developed in the laboratory of NanoEngineering Professor Shaochen Chen.

Current fabrication techniques, such as photolithography and micro-contact printing, are limited to generating simple geometries or 2D patterns.

Stereolithography is best known for its ability to print large objects such as tools and car parts. The difference, said Chen, is in the micro- and nanoscale resolution required to print tissues that mimic nature's fine-grained details, including blood vessels, which are essential for distributing nutrients and oxygen throughout the body.

Without the ability to print vasculature, an engineered liver or kidney, for example, is useless in regenerative medicine. With DOPsL, Chen's team was able to achieve more complex geometries common in nature such as flowers, spirals and hemispheres. Other current 3D fabrication techniques, such as two-photon photopolymerization, can take hours to fabricate a 3D part.

Advertisement

This photo-induced solidification process forms one layer of solid structure at a time, but in a continuous fashion. The technology is part of a new biofabrication technology that Chen is developing under a four-year, 1.5 million dollar grant from the National Institutes of Health.

Advertisement

Details about the technology has been published in the journal Advanced Materials. (ANI)

Source-ANI